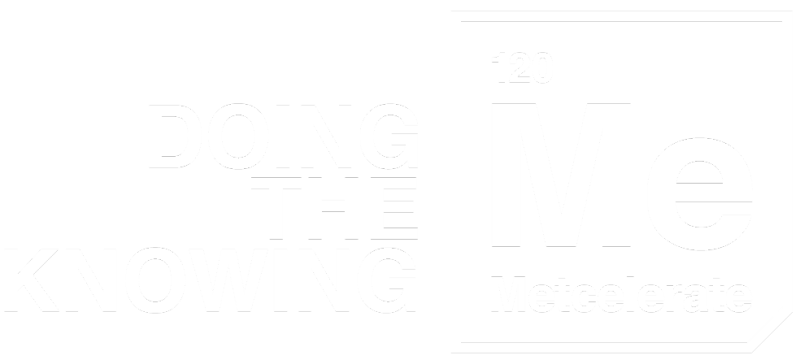

Mineral Processing in the Mining Value Chain

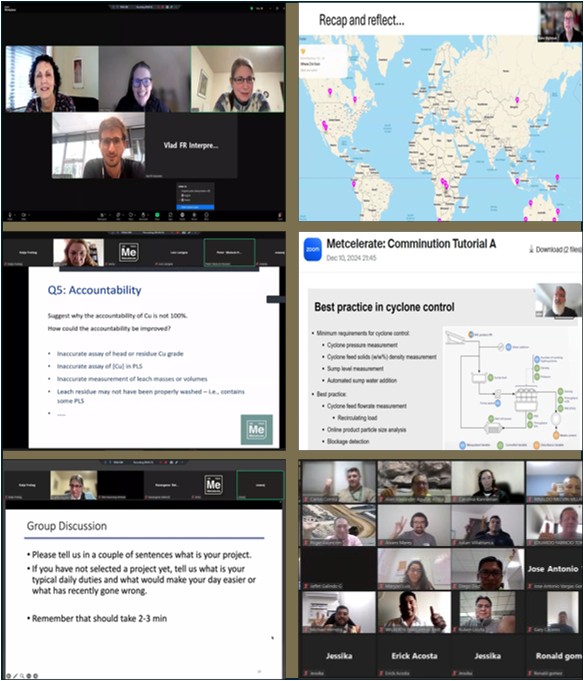

This course serves as the foundation of the Metcelerate Program by examining the full mining value chain and highlighting how

individual roles contribute to overall business performance. Participants will analyze company production and sustainability reports to

understand how operational decisions influence profitability, environmental outcomes, and long-term value. The objective is to help

participants recognize their potential to impact bottom-line performance, either positively or negatively.

Key learning outcomes include the ability to:

-

Identify key operational objectives based on information in company reports.

-

Develop a simple revenue model using operational data.

-

Understand the organization's safety, environmental, and social responsibility commitments.

Process Mineralogy

This course helps learners understand how the characteristics of ore minerals — including their composition, texture, and

associations — fundamentally control the economic and environmental outcomes of mineral processing, and how both valuable and gangue

minerals influence these results. Key concepts such as mineral properties, texture, liberation, and deposit type are reviewed, together with

the main mineralogical characterization tools used in industry. The approach is practical and focused on operational

decision-making.

Key learning outcomes include the ability to:

-

Understand how mineralogical analysis can be used to manage and improve process performance.

-

Recognize the main mineral characterization techniques and when to apply them.

-

Use mineralogical information to diagnose processing issues and support technical decision-making.

Experimental Design and Statistics

This course introduces experimental design and statistical tools as a foundation for data analysis in mineral processing. It explains

how to structure trials, interpret results, and reduce uncertainty in technical decision-making. Key concepts such as hypothesis testing,

regression, and principles of experimental design are reviewed, with a practical focus on solving operational problems using plant and

laboratory data.

Key learning outcomes include the ability to:

-

Understand how structured experimental design improves the quality of technical decisions.

-

Recognize and apply key statistical tools appropriate to mineral processing data.

-

Design, analyze, and evaluate trials using sound statistical criteria.

Comminution

This course covers the theoretical and practical foundations of comminution, integrating key principles of fragmentation, size

reduction, and the operation of crushing and grinding circuits. It explores the relationship between energy input and particle size

reduction, reviews the technical characteristics of conventional and emerging equipment, and introduces current approaches to monitoring,

modelling, optimization, and process control. The course combines theory with applied analysis, with a strong emphasis on performance

evaluation and continuous improvement of comminution operations.

Key learning outcomes include the ability to:

-

Understand the fundamental principles of breakage and size reduction in crushing and grinding.

-

Recognize the main technologies and circuit configurations used in comminution.

-

Apply analytical and modelling tools to evaluate and optimize comminution performance.

Flotation

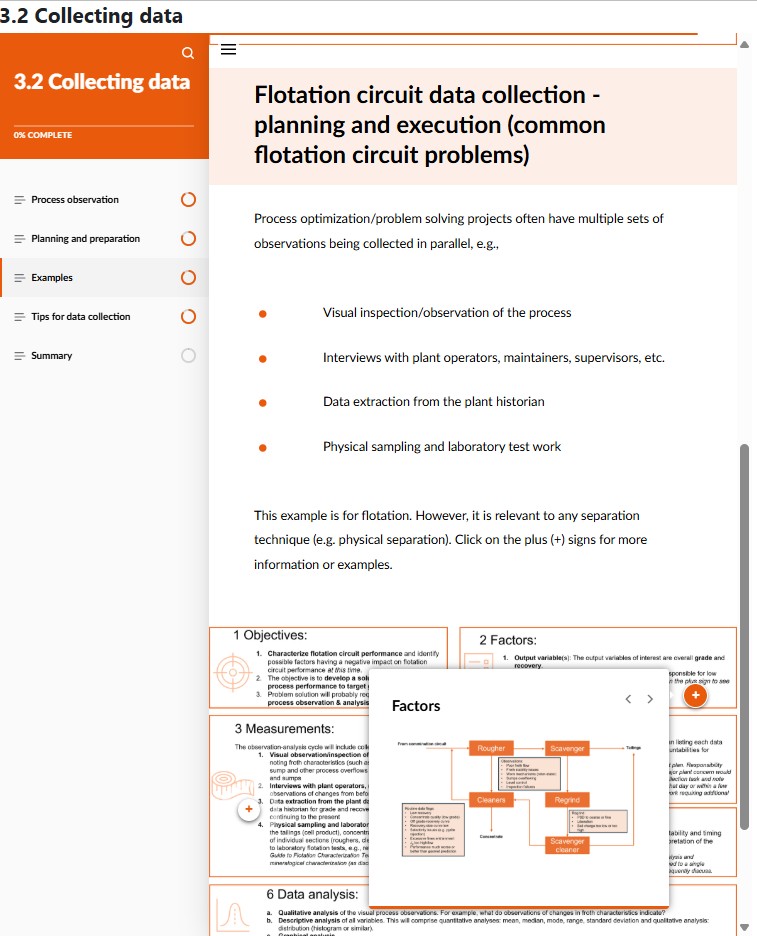

This course covers the fundamental principles and leading practices in mineral flotation, examining the physical and chemical factors

that influence flotation performance across the mineral surface, pulp, and froth phases. Tools and techniques for measuring and monitoring

flotation circuits are introduced, together with the concept of reaction kinetics as a foundation for understanding flotation models and

predicting circuit performance. These principles are linked to practical approaches for circuit diagnosis and optimization, supported by

examples from representative industrial operations.

Key learning outcomes include the ability to:

-

Understand the physical and chemical principles of flotation and how they apply to equipment and circuit performance.

-

Recognize best practices for monitoring, controlling, and managing flotation operations.

-

Apply analytical and scientific approaches to diagnose performance and develop optimization strategies.

Physical Separation

This course provides a high-level overview of physical separation methods used in mineral processing, distinguishing between

solid-liquid and solid-solid separation, and is delivered in two parts that may be taken separately. It introduces the underlying technical

principles and illustrates their application, including their use to pre-concentrate ore, reject waste early, and recover high-value

components such as coarse gold or magnetite. Processes include dewatering by thickening and filtration, gravity separation in aqueous or

dense media, magnetic and electrical separation, and sensor-based sorting, together with the principles that guide their selection and

performance.

Key learning outcomes include the ability to:

-

Understand the principles and common methods of solid-liquid separation, with a focus on thickening and filtration.

-

Recognize solid-solid separation techniques based on differences in particle properties, such as gravity, magnetic, electrical, and sensor-based sorting.

-

Explain the fundamental principles that govern the selection and performance of dewatering and physical separation methods.

Hydrometallurgy

This course introduces the fundamentals of hydrometallurgy within the context of mineral processing. It provides an overview of

leaching chemistry, the key factors that influence reaction rates and metal recovery, and the main process configurations used in practice,

together with a brief overview of downstream purification and recovery stages. The course is designed to build awareness and understanding

of key concepts and issues rather than to develop advanced technical expertise, helping participants recognize when hydrometallurgical

considerations are important in operational and decision-making contexts.

Key learning outcomes include the ability to:

-

Understand the fundamental principles of leaching and the factors that control its performance.

-

Recognize the main hydrometallurgical process configurations and technologies.

-

Explain the role of leaching within the overall metal recovery process and its impact on downstream stages.

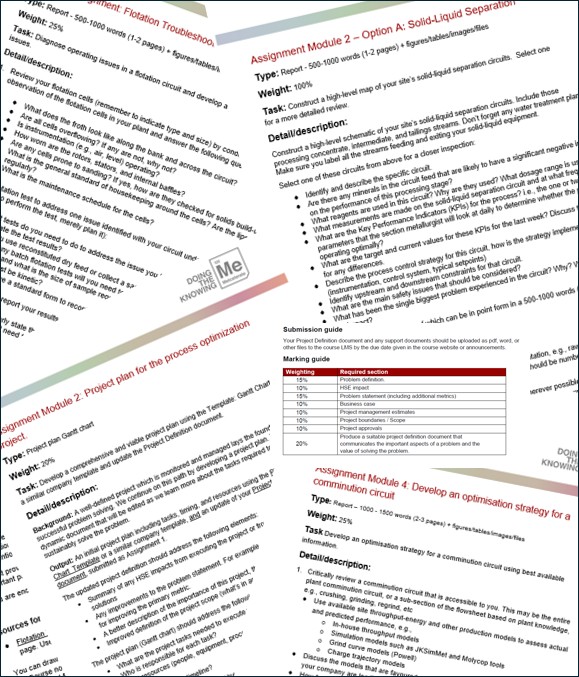

Process Optimization Project

The capstone of the program is a process optimization project, where participants apply the knowledge and skills gained throughout

the courses to a real workplace challenge. Working individually or in small groups, participants identify an operational issue at their

plant and design a structured technical investigation to address it. This hands-on experience builds confidence, strengthens problem-solving

capability, and delivers tangible value to their organization.

Key learning outcomes include the ability to:

-

Successfully complete a meaningful technical project that delivers measurable value to the organization.

-

Define clear project objectives and develop a structured execution plan.

-

Apply problem-solving and project management skills in a real operational environment.