Fulfill your potential. Transform your impact.

Learn the skills you need to unleash your talent and make your mark.

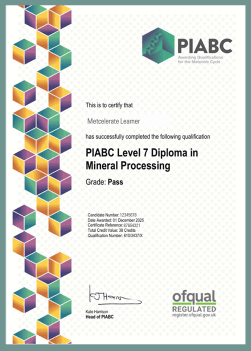

Right now, Metcelerate Program participants around the globe are acquiring the training they need to improve operational expertise, make smarter decisions, and achieve peak metallurgical performance. Will you be part of our next cohort?