World-renowned practitioners.

World-leading training.

Put your professional development in the hands of the experts.

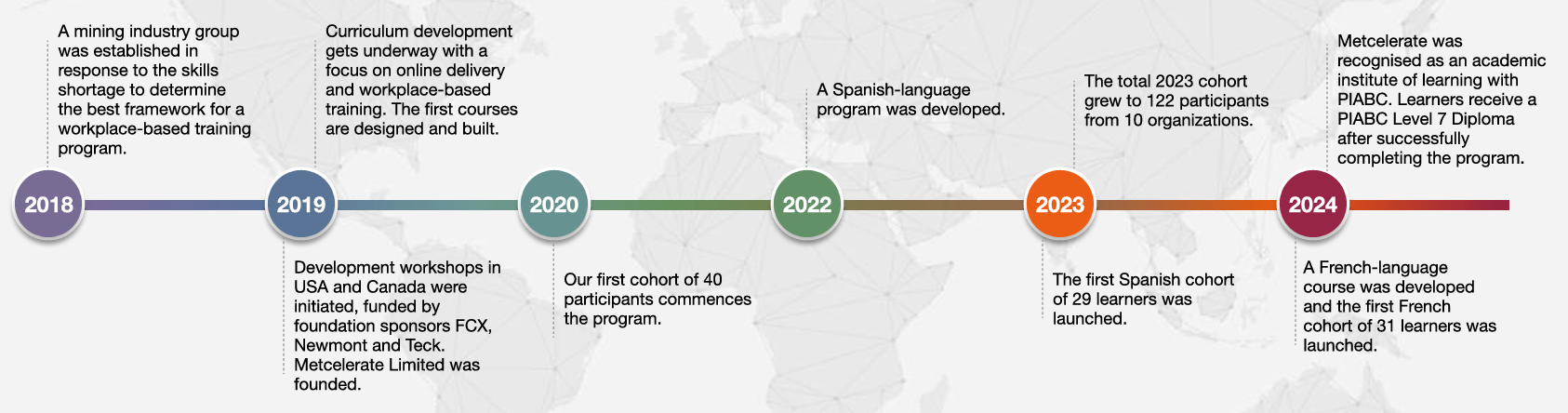

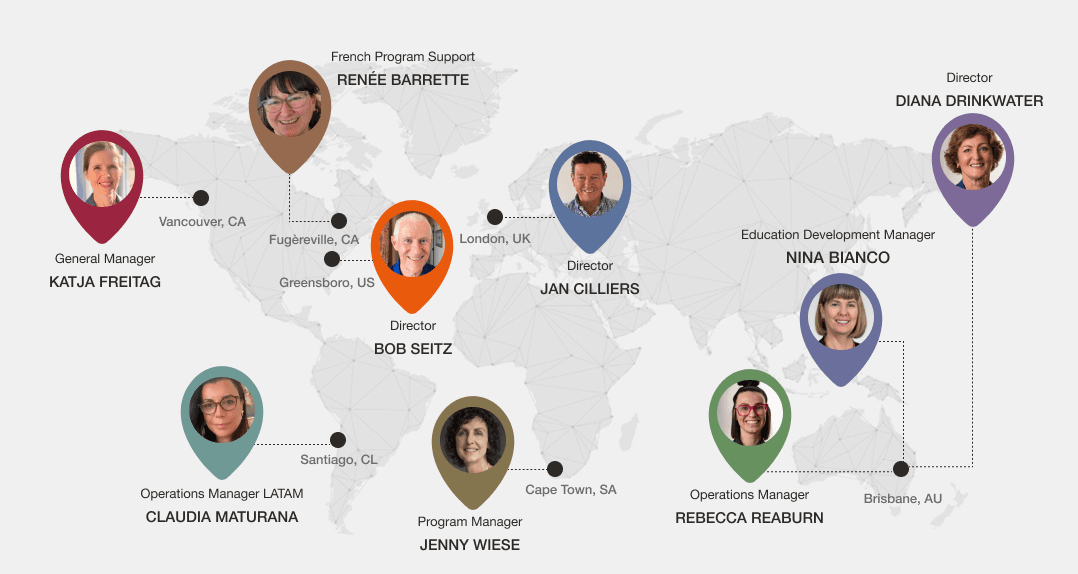

Metcelerate is unique. No other organization is designed from the ground up to address our industry’s skills gaps. No other organization can apply the same degree of proven expertise in developing metallurgical talent for your organization. You’re in safe hands with Metcelerate.